300's RESTORATION

300 SPENT 29 YEARS INSIDE A WAREHOUSE BEFORE BEING DONATED

TO OUR ORGANIZATION ON

OCTOBER 9TH, 2020.

All of the interior walls were cleaned, primed and repainted Pullman Bedroom Tan. The ceiling was repainted White. The old carpet was removed. The original tile floor was removed and new flooring was installed. All of the stainless steel was cleaned and polished. All of the wood paneling was cleaned and polished. All of the incandescent light bulbs were replaced with warm white LED bulbs.

The generator was serviced. New rubber hoses were installed. The filters and fluids were changed. New batteries were installed. The air conditioning system was serviced and converted to R134a. The heating system was serviced. The refrigeration system was serviced and converted to R134a. The non-functioning Vapor hot water heating system was removed and a brand new in-line hot water heating system was installed. The faucets in the kitchen and bathrooms were rebuilt.

The entire car was blasted to bare metal, removing 67 years of paint layers . Body work was completed. The rotting platform C-channel supports were removed and new supports were welded in place. The 1/4" diamond plate on the platform was removed and replaced with 3/8" diamond plate. Three areas of body corrosion were cut out and patch panels were welded into place. The worn out Freightmaster draft gear was removed and a new Strato buff and draft pack was installed. The kitchen end diaphram was removed and replaced with new rubber. The kitchen end buffer plate was removed and straightened. The car received one coat of Imron primer, two coats on Imron top coat, and two coats of Imron clear coat.

LOUNGE

BEFORE

DURING

AFTER

BEDROOM HALLWAY

BEFORE

DURING

AFTER

BEDROOM C

BEFORE

DURING

AFTER

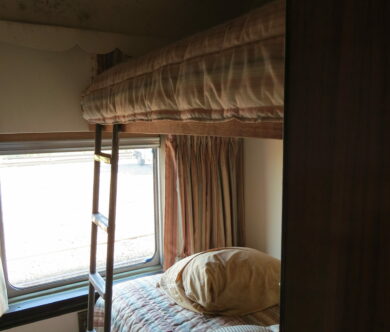

BEDROOM B

BEFORE

DURING

AFTER

BATHROOM B

BEFORE

DURING

AFTER

BEDROOM A

BEFORE

DURING

AFTER

DINING ROOM

BEFORE

DURING

AFTER

KITCHEN

BEFORE

DURING

AFTER

EXTERIOR

2018

2021

2022

2024

2024

2024

A GOOGLE PHOTOS ALBUM COVERING OUR JOURNEY FROM THE INITIAL INSPECTION TO THE PRESENT CAN BE SEEN BY CLICKING ON THE PHOTO BELOW

MAKE A DONATION

Our preservation efforts are funded entirely through memberships, ticket sales and especially grants and private donations. Each donation makes a tremendous impact!

BE A VOLUNTEER

Memberships strengthen the backbone of our organization and directly support the operation and preservation of 300.